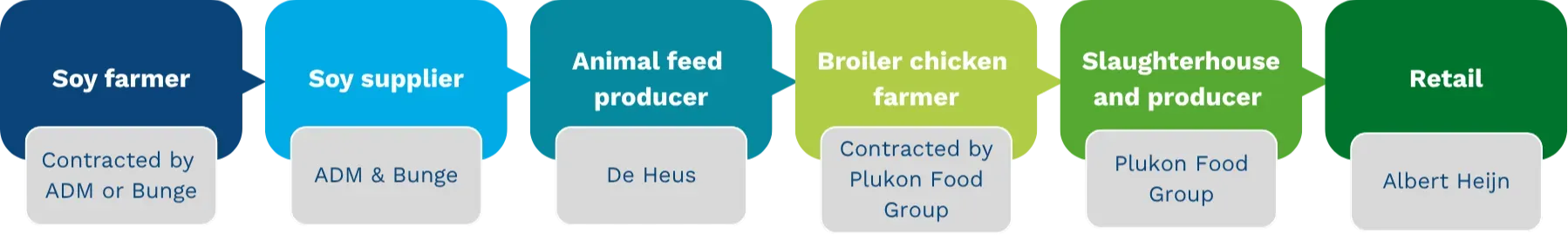

As sustainability becomes central to the agri-food sector, companies are looking for credible, data-driven ways to show real impact — from farm-level sourcing to product-level claims. The Chain of Custody plays a key role in linking sustainability commitments to verified supply chain data, ensuring that raw materials are credibly sourced, traced, and accounted for.

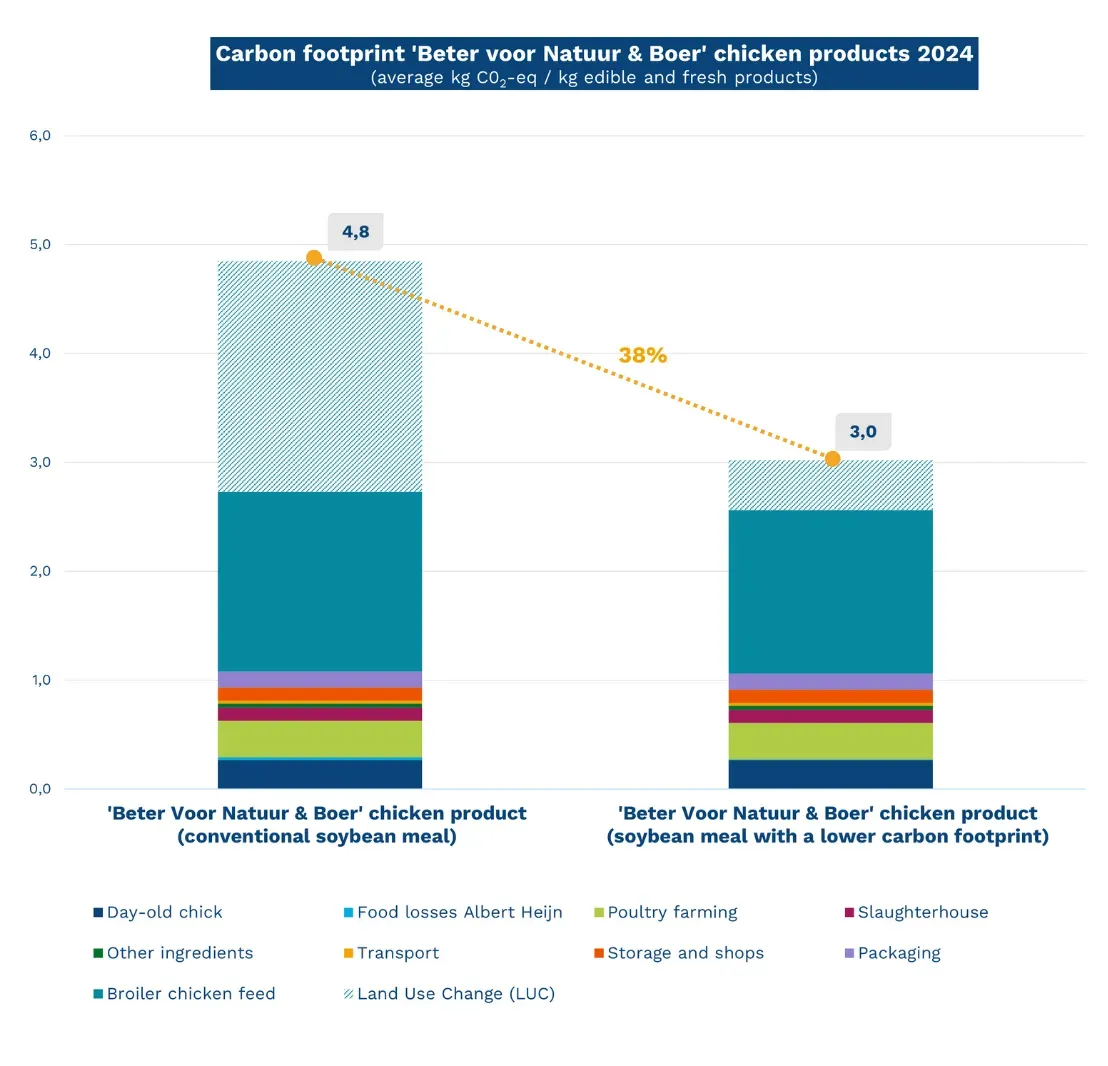

Working together across the entire supply chain is key. You might move faster on your own, but together you achieve more. And that’s exactly what Albert Heijn has done, bringing together all supply chain partners to create a more sustainable chicken supply chain. We had the opportunity to provide strategic sustainability advice on the application of the Chain of Custody for chicken feed. This enables Albert Heijn and the supply chain partners to source feed ingredients with a lower carbon footprint and consequently reduce the carbon footprint of chicken products. A scenario analysis shows that the reduction potential for the carbon footprint of fresh and natural chicken products is 38%.

This case demonstrates how joint efforts in the supply chain and combining Chain of Custody systems with robust Life Cycle Assessment (LCA) analysis can unlock real, measurable progress toward more sustainable food systems.